- ● Product List

- Tungsten Carbide Drawing Dies

- Tungsten Carbide Wire Drawing Dies

- -S01 Carbide Drawing Die for Ferrous Metal Wire

- -S10 Carbide Drawing Die for Ferrous Metal Wires

- -S11 Carbide Drawing Die for Ferrous Metal Wires

- -S11 (Improved Type) Carbide Drawing Die for Metal Wire

- -W Type Carbide Drawing Dies for Metal Wire

- -W1 Type Carbide Drawing Die for Metal Wires

- -V Type Carbide Drawing Die for Metal Wire

- -LV Type Carbide Drawing Die for Metal Wire

- -E Type Carbide Drawing Die for Metal Wires

- -A Type Carbide Drawing Die for Metal Wires

- -R4 Carbide Drawing Die for Metal Wires

- -R5 Carbide Drawing Die for Metal Wires

- -R6 Carbide Drawing Die for Metal Wires

- -S01 Carbide Drawing Die for Non-Ferrous Metal Wire

- -S10 Carbide Drawing Die for Non-Ferrous Metal Wire

- -S12 Carbide Drawing for Non-Ferrous Metal Wire

- -LSV Wire Die for Steel Cord

- -GS1 Wire Drawing Die

- Tungsten Carbide Bar Drawing Dies

- Tungsten Carbide Tube Drawing Dies

- Tungsten Carbide Tube Drawing Dies Plug

- Carbide Rolls

- Carbide Roll Rings

- Grooved Roller

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Wire Guide Die

- Powder Coating Die

- Peeling Dies

- Custom Drawing Dies

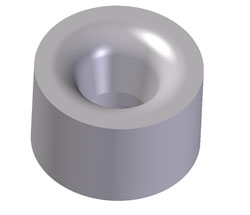

W1 Type Carbide Drawing Die for Metal Wires

W1 cemented carbide drawing dies for ferrous metal wires are used to stretch ferrous metal wires into longer and thinner ones. When wires are pulled through dies, diameter of wires decreases, while length increases. For W1 carbide wire drawing dies, diameter of stretched wires ranges from 0.5 mm to 20 mm. W1 drawing dies are widely used in metallurgical industry.

Features1. W1 cemented carbide drawing dies for ferrous metal wires are featured by high melting point, good corossion resistance, long working life and high cost performance ratio.

2. We can manufacture custom carbide wire drawing dies according to design draft offered by customers.

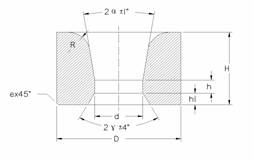

3. Fine design in several important structures, including entrance area, lubrication area, working area, etc., reduces electric energy loss and increases working efficiency.

1. Let us know your requirements on metal materials and desirable wire drawing die models, then, we can offer you with right cemented carbide drawing dies for ferrous metal wires.

2. As to custom carbide wire drawing dies, if you provide a physical prototype, only 15 days are needed for production of this kind of carbide wire drawing die. While, if you provide only a design drawing, time needed is 25 days.

3. Payment is by T/T or L/C.

4. Cemented carbide drawing dies for ferrous metal wires are placed in fiber board cases and delivered by sea, or placed in cartons by air. Besides, packaging for cargos meets standard stipulations.

| New Type | Old Type | Dimension (mm) | Reference Dimension (mm) | |||||||||

| D | H | d | 2α | 2β | 2γ | h | h1 | h2 | R | E | ||

| W1-0120810-0.5 | W103¢0.5 | 12 | 8 | 0.5 | 10° | 90° | 60° | 0.3 | 1.2 | 2.0 | 2.0 | 1.0 |

| W1-0120810-0.8 | W103¢0.8 | 12 | 8 | 0.8 | 10° | 90° | 60° | 0.6 | 1.2 | 2.3 | 2.0 | 1.0 |

| W1-0120810-1.0 | W103¢1.0 | 12 | 8 | 1.0 | 10° | 90° | 60° | 0.7 | 1.6 | 3.6 | 2.0 | 1.0 |

| W1-0120810-1.2 | W103¢1.2 | 12 | 8 | 1.2 | 10° | 90° | 60° | 0.8 | 1.8 | 3.4 | 2.0 | 1.0 |

| W1-0120810-2.0 | W103¢2.0 | 12 | 8 | 2.0 | 10° | 90° | 60° | 1.2 | 1.6 | 3.6 | 2.0 | 1.0 |

| W1-0120810-2.2 | W103¢2.2 | 12 | 8 | 2.2 | 10° | 90° | 60° | 1.2 | 1.6 | 3.6 | 2.0 | 1.0 |

| W1-0120810-2.5 | W103¢2.5 | 12 | 8 | 2.5 | 10° | 90° | 60° | 1.2 | 1.6 | 3.6 | 2.0 | 1.0 |

| W1-0151012-0.8 | W104¢0.8 | 15 | 10 | 0.8 | 12° | 60° | 60° | 0.6 | 2.5 | 4.2 | 2.0 | 1.0 |

| W1-0151012-1.2 | W104¢1.2 | 15 | 10 | 1.2 | 12° | 60° | 60° | 1.0 | 2.0 | 4.8 | 2.0 | 1.0 |

| W1-0151012-1.8 | W104¢1.8 | 15 | 10 | 1.8 | 12° | 60° | 60° | 1.2 | 2.0 | 4.8 | 2.0 | 1.0 |

| W1-0151012-2.6 | W104¢2.6 | 15 | 10 | 2.6 | 12° | 60° | 60° | 1.3 | 2.0 | 4.5 | 3.0 | 1.0 |

| W1-0151012-3.0 | W104¢3.0 | 15 | 10 | 3.0 | 12° | 60° | 60° | 1.4 | 2.0 | 4.5 | 3.0 | 1.0 |

| W1-0201414-1.2 | W105¢1.2 | 20 | 14 | 1.2 | 14° | 60° | 60° | 0.8 | 3.0 | 6.5 | 3.0 | 1.0 |

| W1-0201414-1.4 | W105¢1.4 | 20 | 14 | 1.4 | 14° | 60° | 60° | 1.0 | 3.0 | 6.5 | 3.0 | 1.0 |

| W1-0201414-1.8 | W105¢1.8 | 20 | 14 | 1.8 | 14° | 60° | 60° | 1.2 | 3.0 | 6.5 | 3.0 | 1.0 |

| W1-0201414-2.0 | W105¢2.0 | 20 | 14 | 2.0 | 14° | 60° | 60° | 1.4 | 3.0 | 6.0 | 3.0 | 1.0 |

| W1-0201414-2.2 | W105¢2.2 | 20 | 14 | 2.2 | 14° | 60° | 60° | 1.2 | 3.0 | 6.0 | 3.0 | 1.0 |

| W1-0201414-2.4 | W105¢2.4 | 20 | 14 | 2.4 | 14° | 60° | 60° | 1.3 | 3.0 | 6.0 | 3.0 | 1.0 |

| W1-0201414-3.2 | W105¢3.2 | 20 | 14 | 3.2 | 14° | 60° | 60° | 1.6 | 3.0 | 6.5 | 3.0 | 1.0 |

| W1-0201414-3.4 | W105¢3.4 | 20 | 14 | 3.4 | 14° | 60° | 60° | 1.6 | 3.0 | 6.5 | 3.0 | 1.0 |

| W1-0201414-3.6 | W105¢3.6 | 20 | 14 | 3.6 | 14° | 60° | 60° | 1.7 | 3.0 | 7.0 | 3.0 | 1.0 |

| W1-0201414-3.8 | W105¢3.8 | 20 | 14 | 3.8 | 14° | 60° | 60° | 1.9 | 3.0 | 7.0 | 3.0 | 1.0 |

| W1-0201414-4.0 | W105¢4.0 | 20 | 14 | 4.0 | 14° | 60° | 60° | 1.9 | 3.0 | 7.0 | 3.0 | 1.0 |

| W1-0201414-4.2 | W105¢4.2 | 20 | 14 | 4.2 | 14° | 60° | 60° | 1.9 | 3.0 | 7.0 | 3.0 | 1.0 |

| W1-0201414-4.6 | W105¢4.6 | 20 | 14 | 4.6 | 14° | 60° | 60° | 1.9 | 3.0 | 7.0 | 3.0 | 1.0 |

| W1-0201414-4.8 | W105¢4.8 | 20 | 14 | 4.8 | 14° | 60° | 60° | 1.9 | 3.0 | 7.0 | 3.0 | 1.0 |

| W1-0201414-5.0 | W105¢5.0 | 20 | 14 | 5.0 | 14° | 60° | 60° | 2.0 | 3.0 | 7.0 | 3.0 | 1.0 |

| W1-0201414-5.2 | W105¢5.2 | 20 | 14 | 5.2 | 14° | 60° | 60° | 2.0 | 3.0 | 7.0 | 3.0 | 1.0 |

| W1-0201414-5.5 | W105¢5.5 | 20 | 14 | 5.5 | 14° | 60° | 60° | 2.0 | 3.0 | 7.0 | 3.0 | 1.0 |

| W1-0251814-5.4 | W106¢5.4 | 25 | 18 | 5.4 | 14° | 60° | 60° | 2.0 | 4.0 | 7.5 | 5.0 | 1.2 |

| W1-0251814-5.6 | W106¢5.6 | 25 | 18 | 5.6 | 14° | 60° | 60° | 2.4 | 4.0 | 7.5 | 5.0 | 1.2 |

| W1-0251814-6.0 | W106¢6.0 | 25 | 18 | 6.0 | 14° | 60° | 60° | 2.6 | 4.0 | 7.5 | 5.0 | 1.2 |

| W1-0251814-6.6 | W106¢6.6 | 25 | 18 | 6.6 | 14° | 60° | 60° | 2.6 | 4.0 | 7.5 | 5.0 | 1.2 |

| W1-0251814-7.0 | W106¢7.0 | 25 | 18 | 7.0 | 14° | 60° | 60° | 2.6 | 4.0 | 7.5 | 5.0 | 1.2 |

| W1-0251814-7.6 | W106¢7.6 | 25 | 18 | 7.6 | 14° | 60° | 60° | 2.6 | 4.0 | 7.5 | 5.0 | 1.2 |

| W1-0302216-8.2 | W107¢8.2 | 30 | 22 | 8.2 | 16° | 60° | 60° | 3.1 | 5.0 | 8.5 | 5.0 | 1.2 |

| W1-0302216-8.8 | W107¢8.8 | 30 | 22 | 8.8 | 16° | 60° | 60° | 3.3 | 5.0 | 8.5 | 5.0 | 1.2 |

| W1-0302216-9.6 | W107¢9.6 | 30 | 22 | 9.6 | 16° | 60° | 60° | 3.5 | 5.0 | 8.5 | 5.0 | 1.2 |

| W1-0352516-10.6 | W108¢10.6 | 35 | 25 | 10.6 | 16° | 60° | 60° | 3.5 | 5.0 | 8.5 | 5.0 | 1.2 |

| W1-0352516-11.0 | W108¢11.0 | 35 | 25 | 11.0 | 16° | 60° | 60° | 3.5 | 5.0 | 8.5 | 5.0 | 1.2 |

| W1-0352516-11.2 | W108¢11.2 | 35 | 25 | 11.2 | 16° | 60° | 60° | 3.8 | 5.0 | 8.5 | 5.0 | 1.2 |

| W1-0352516-11.6 | W108¢11.6 | 35 | 25 | 11.6 | 16° | 60° | 60° | 3.8 | 5.0 | 8.5 | 5.0 | 1.2 |

| W1-0352516-12.2 | W108¢12.2 | 35 | 25 | 12.2 | 16° | 60° | 60° | 3.8 | 5.0 | 8.5 | 5.0 | 1.2 |

| W1-0402716-13.0 | W109¢13.0 | 40 | 27 | 13.0 | 16° | 60° | 60° | 4.0 | 5.0 | 11 | 6.0 | 1.5 |

| W1-0503016-16.0 | W109¢16.0 | 50 | 30 | 16.0 | 16° | 60° | 60° | 5.0 | 5.0 | 13 | 6.5 | 1.5 |

Our cemented carbide drawing dies for ferrous metal wires are commonly used in iron industry and steel industry. They are inspected under strict quality tests and have passed ISO9001:2000. Besides, our carbide wire drawing dies are widely sold at home and abroad. They are mainly exported to North American countries, Japan, Korea, India, Taiwan, Southeast Asia, etc.

- Peeling Dies

- Tungsten carbide peeling dies have different specifications, such as round, square, hexagonal, deltoid and other custom shapes. They are broadly ...

- Custom Drawing Dies

- TallKee Cemented Carbide Co., Ltd. is a professional manufacturer and supplier of tungsten carbide drawing dies. Our custom drawing dies ...