- ● Product List

- Tungsten Carbide Drawing Dies

- Tungsten Carbide Wire Drawing Dies

- Tungsten Carbide Bar Drawing Dies

- Tungsten Carbide Tube Drawing Dies

- Tungsten Carbide Tube Drawing Dies Plug

- Carbide Rolls

- Carbide Roll Rings

- Grooved Roller

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Wire Guide Die

- Powder Coating Die

- Peeling Dies

- Custom Drawing Dies

Custom Drawing Dies

TallKee Cemented Carbide Co., Ltd. is a professional manufacturer and supplier of tungsten carbide drawing dies. Our custom drawing dies are characterized by good wear resistance, high precision and good surface smoothness. We not only provide qualified products with reasonable price, but also provide custom services for our clients. When you customize our carbide drawing dies, you should pay attention to the relief angle and bearing geometry. They are the key factors in achieving rapid die finishing and best die performance. For the smallest bores, drawing and exit cones must be perfectly co-axial so as to achieve an accurate final geometry.

MaterialWith rich experience and commitment to research and development, we can offer a wide range of carbide grades to meet the drawing requirements for all applications.

Grades Properties and Recommended Applications of Carbide Drawing Dies Wear Parts| Grade | Physical and Mechanical Properties | Application Recommended | ||

| Density | Hardness | T.R.S | ||

| G/cm3 | HRA | N/mm2 | ||

| LZ05 | 15.0~15.4 | 91.5 | 1300 | With excellent wear resistant, it is used for making small custom drawing dies. |

| LZ10 | 14.7~15.1 | 89.5 | 1670 | With high resistance to wear, it can make small and medium size drawing dies. |

| LZ10.1 | 14.8~15.1 | 91.0 | 1560 | Excellent wear resistance, it is suitable for drawing the wires, nonferrous wires and rods within 6mm size. |

| LZ10.2 | 14.4~14.7 | 91.0 | 1610 | Mainly used for manufacturing strips and disc cutters and also for other tools. |

| LZ15 | 14.7~15.0 | 89.5 | 1720 | Excellent wear resistance and toughness, suitable for making carbide drawing dies for wires and rods with various sizes. |

| LZ20 | 14.6~14.9 | 89.0 | 1840 | With good toughness and wear resistance, it is mainly used to make custom drawing dies for stretching wires and rods. |

| LZ25 | 14.0~14.4 | 87.0 | 2000 | |

| LZ30 | 13.9~14.2 | 86.5 | 2200 | Used for punching dies, stamping dies and wear resistance parts. LZ30.1 is used in scissors and LZ30.2 is mainly used for three-dimensional roller. |

| LZ30.1 | 13.9~14.2 | 86.5 | 2200 | |

| LZ30.2 | 13.9~14.2 | 86.5 | 2300 | |

| LZ50 | 13.6~13.9 | 86.0 | 2200 | |

| LD10 | 14.0~14.2 | 86.5 | 2500 | |

| LZ55 | 13.4~13.7 | 84.5 | 2500 | High bending strength, used for stamping dies |

| LL10.5 | 14.25~14.65 | 91.5 | 1800 | An ultra fine cemented carbide with tungsten powder and binder cobalt. Good toughness and abrasion resistance, it is mainly used for disc cutters and also for other tools. |

| LD30 | 14.8~15.0 | 89.5 | 2000 | Universal grades widely used in machining tools for cast iron, nonferrous metals and their alloys and nonmetal materials, wear parts, and tools for machining other alloys |

| LD20 | 14.7~14.9 | 89.0 | 2200 | |

| LC30 | 13.9~14.2 | 85.0 | 2500 | Excellent wear-resistant properties and toughness, suitable for making the shock resistant forging dies and hot-pressing forging dies. |

| LC40 | 13.8~14.1 | 84.0 | 2600 | With good resistance to wear and toughness, it is suitable for making the shock resistant forging die and hot-pressing forging dies. |

| LC50 | 13.6~13.9 | 83.0 | 2450 | Excellent wear resistance and toughness, suitable for making punching dies and hot-pressing forging dies. |

| LC60 | 13.4~13.7 | 82.5 | 2450 | With wear-resistant properties and toughness, suitable for making the punching and impacting dies for standard parts |

| LC70 | 13.2~13.5 | 82.0 | 2450 | Good wear-resistant properties and toughness, suitable for punching the nuts and stainless bolts under the large loading condition of punching and impacting. |

| LC80 | 13.0~13.3 | 80.0 | 2400 | Excellent abrasion resistance and toughness, suitable for making hot-revolve press die and large loading condition of punching and impacting forming. |

When using our carbide drawing dies, please choose the Grade according to the drawing way and properties of the drawing material, it’s important to the drawing work. Therefore, please select the carbide grade on the basis of the upper list. If you have any question, please enquire us.

Drawing dies type is consist of item type, OD, height, compress angle and ID parameter.

Example

S11 — 008 06 12 — 1.2

① Symbol of drawing dies’ model.

② Symbol of drawing dies’ OD, expressed by three digitally number, the unit is in mm, if the number is short of three digit, add “0” in the front to fill in it

③ Symbol of drawing dies’ height, expressed by two digitally number, the unit is in mm, if the number is short of two digit, add “0” in the front to fill in it

④ Symbol of drawing dies’ compress angle, expressed by two digitally number, the unit is in “ ° ” if have no compress angle, expressed by “00”.

⑤ Symbol of drawing dies’ ID

Round inner hole is expressed by ID size “d”, the unit is in mm; when ID size is less than 1mm, use two digitally integer, when ID size is lager than 1mm, use one digitally integer.

Quadrangle inner hole is expressed by hole length × hole width , the unit is in mm, use one digitally.

Hexagon inner hole is expressed by inscribed circle’ size “s”, the unit is in mm, use one digitally.

30 type, 30-A type, 30-A F type

① Symbol of drawing dies model.

② Symbol of drawing dies’ ID, expressed by two digitally number, the unit is in mm, if the number is short of two digit, add “0” in the front to fill in it

③ Symbol of drawing dies’ height, expressed by two digitally number, the unit is in mm, if the number is short of two digit, add “0” in the front to fill in it

④ Symbol of drawing dies OD compress angle, expressed by two digitally number, the unit is in “ ° ”

⑤ Symbol of drawing dies OD

Types 30-AB still adapt the old type.

- Tungsten Carbide Tube Drawing Dies

- Tungsten carbide tube drawing dies are designed with round, square, hexagon and other special shapes. They are used for drawing various ...

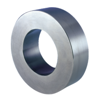

- Carbide Roll Rings

- Carbide roll rings refer to installing a series of rotary roll surface through bearings on the arc core shaft, so as to achieve flattening effect ...