- ● Product List

- Tungsten Carbide Drawing Dies

- Tungsten Carbide Wire Drawing Dies

- Tungsten Carbide Bar Drawing Dies

- Tungsten Carbide Tube Drawing Dies

- Tungsten Carbide Tube Drawing Dies Plug

- Carbide Rolls

- Carbide Roll Rings

- Grooved Roller

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Wire Guide Die

- Powder Coating Die

- Peeling Dies

- Custom Drawing Dies

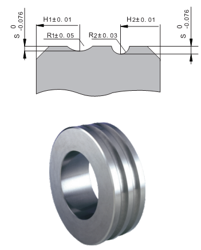

Grooved Roller

Tungsten carbide rollers possess resistance to thermal cracks and corrosion due to adding nickel and chromium in the binder. It can reduce the depth and width of micro cracks in grooved rollers, extend the service life and obtain high tonnage and good surface quality. If the PH of cooling water is less than 7.2, tungsten carbide rollers will show their special superiority.

Features of Grooved Roller1. The tungsten carbide roller has excellent heat-conducting property, high abrasion resistance and corrosion resistance.

2. Under normal temperature, the hardness can reach HRA78~95. Under high temperature, they also own excellent red hardness.

3. The coefficient of linear expansion of grooved roller is about 0.35 to 0.65 times of the steels with the temperature between 20℃ and 400℃.

4. The tungsten carbide roller has high density, which ranges from 12.6g/cm3 to 14.9g/cm3.

5. We have our own grades for carbide rolls.

The external diameter of this tungsten carbide roller ranges from 145 mm to 380 mm.

Physical and Mechanical Properties of LR Series Grooved Roller| Grade | Chemical Composition % | Density g/mm3 | Hardness HPA | Bending Strength N/mm2 | Compressive Strength N/mm2 | Thermal Conductivity Cal/cm.sec.C | Coefficient of Thermal Expansion 10-6/K | |

| WC | Co+Ni+Cr | |||||||

| LR20 | 89 | 11 | 14.3 | ≥86.0 | ≥2200 | 3400 | 0.2 | 6.0 |

| LR25 | 87 | 13 | 14.1 | ≥84.0 | ≥2200 | 3400 | 0.2 | 6.0 |

| LR30 | 85 | 15 | 13.9 | ≥83.0 | ≥2300 | 3200 | 0.2 | 6.1 |

| LR40 | 82 | 18 | 13.6 | ≥82.0 | ≥2300 | 3200 | 0.2 | 6.2 |

| LR45 | 80 | 20 | 13.5 | ≥81.0 | ≥2200 | 3000 | 0.14 | 6.4 |

| LR55 | 75 | 25 | 13.0 | ≥80.0 | ≥2200 | 2800 | 0.17 | 6.8 |

| LR60 | 70 | 30 | 12.8 | ≥79.0 | ≥2100 | 2700 | 0.15 | 7.0 |

| Grade | Hardness (HV) | Bending Strength (N/mm2) | ||||

| 20℃ | 300℃ | 600℃ | 20℃ | 300℃ | 600℃ | |

| LR20 | 1000 | 750 | 600 | 2200 | 2100 | 2000 |

| LR25 | 1000 | 750 | 600 | 2200 | 2100 | 2000 |

| LR30 | 900 | 700 | 550 | 2300 | 2200 | 2000 |

| LR40 | 750 | 650 | 530 | 2300 | 2100 | 2000 |

| LR45 | 730 | 600 | 500 | 2250 | 2100 | 2000 |

| LR55 | 700 | 550 | 450 | 2200 | 2000 | 1900 |

| LR60 | 680 | 830 | 430 | 2100 | 1900 | 1800 |

An overall understanding of the properties of all kinds of cemented carbide grades is the basis for properly choosing the grades for tungsten carbide rollers.

Packaging and Payment

1. Standard packing or neutral packing is available.

2. Our grooved rollers can be paid by telegraphic transfer and letter of credit.

TallKee Cemented Carbide Co., Ltd is a professional manufacturer and supplier of tungsten carbide roller in China. In addition to grooved rollers, we have carbide roll rings, carbide wire drawing dies and tube drawing dies. We have passed ISO90012000 International Quality System Certification. Last year, the annual income is 35 million, which includes 20 million export revenue and 15 million home sales.

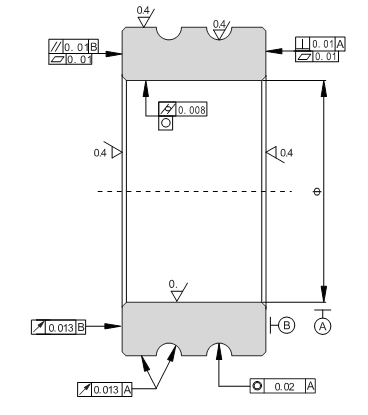

- Carbide Roll Rings

- Carbide roll rings refer to installing a series of rotary roll surface through bearings on the arc core shaft, so as to achieve flattening effect...

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Cemented carbide rolls belong to thread rolls. The high-speed wire generally refers to high speed ...