- ● Product List

- Tungsten Carbide Drawing Dies

- Tungsten Carbide Wire Drawing Dies

- -S01 Carbide Drawing Die for Ferrous Metal Wire

- -S10 Carbide Drawing Die for Ferrous Metal Wires

- -S11 Carbide Drawing Die for Ferrous Metal Wires

- -S11 (Improved Type) Carbide Drawing Die for Metal Wire

- -W Type Carbide Drawing Dies for Metal Wire

- -W1 Type Carbide Drawing Die for Metal Wires

- -V Type Carbide Drawing Die for Metal Wire

- -LV Type Carbide Drawing Die for Metal Wire

- -E Type Carbide Drawing Die for Metal Wires

- -A Type Carbide Drawing Die for Metal Wires

- -R4 Carbide Drawing Die for Metal Wires

- -R5 Carbide Drawing Die for Metal Wires

- -R6 Carbide Drawing Die for Metal Wires

- -S01 Carbide Drawing Die for Non-Ferrous Metal Wire

- -S10 Carbide Drawing Die for Non-Ferrous Metal Wire

- -S12 Carbide Drawing for Non-Ferrous Metal Wire

- -LSV Wire Die for Steel Cord

- -GS1 Wire Drawing Die

- Tungsten Carbide Bar Drawing Dies

- Tungsten Carbide Tube Drawing Dies

- Tungsten Carbide Tube Drawing Dies Plug

- Carbide Rolls

- Carbide Roll Rings

- Grooved Roller

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Wire Guide Die

- Powder Coating Die

- Peeling Dies

- Custom Drawing Dies

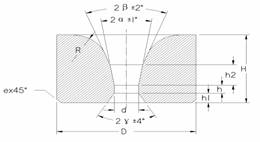

S11 Carbide Drawing Die for Ferrous Metal Wires

S11 tungsten carbide wire drawing dies for ferrous metals can pull large-diameter ferrous metal wires into small-diameter wires whose diameter ranges from 0.3 mm to 12 mm. They are widely used in steel industry. There are several important structures in tungsten carbide drawing dies: entrance area, lubrication area, working area, sizing area, exit area and exit cone angle. Only with all these areas are designed exquisitely, can tungsten carbide wire drawing dies function well and pull high-quality wires.

Features1. During stretching process, small friction coefficient advances working efficiency and greatly reduces electric energy loss.

2. S11 tungsten carbide wire drawing dies for ferrous metals feature high thermal conductivity, which makes heat release quickly during working.

3. Tungsten carbide drawing dies can draw wires into various shapes (cross section), such as hexagon, semicircle, triangular, rectangle, etc. Besides, custom drawing dies for irregular shapes of wires are also provided.

4. They are featured by high cost performance ratio. So, they are popularly sold at home and abroad.

5. S11 wire drawing dies are made from different compositions so that they can meet demands of different ferrous metal wires and satisfy specific requirements for wires.

6. Advanced fine machining technology and sintering process are applied in production of S11 tungsten carbide wire drawing dies for ferrous metals.

With a specialist team, advanced production facilities and more than 3000 m2 area, TallKee Cemented Carbide is capable of manufacturing various cemented carbide dies no matter these dies are complex in structures or irregular in shapes. In details, we can manufacture 3 million tungsten carbide dies and 500 T cemented carbide workblanks every year. Last year, our sales volume in domestic market, including sales volume of S11 tungsten carbide wire drawing dies for ferrous metals, was 15 million RMB, and in overseas market was 20 million RMB.

- Grooved Roller

- Tungsten carbide rollers possess resistance to thermal cracks and corrosion due to adding nickel and chromium in the binder ...

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Cemented carbide rolls belong to thread rolls. The high-speed wire generally refers to high speed ...