- ● Product List

- Tungsten Carbide Drawing Dies

- Tungsten Carbide Wire Drawing Dies

- -S01 Carbide Drawing Die for Ferrous Metal Wire

- -S10 Carbide Drawing Die for Ferrous Metal Wires

- -S11 Carbide Drawing Die for Ferrous Metal Wires

- -S11 (Improved Type) Carbide Drawing Die for Metal Wire

- -W Type Carbide Drawing Dies for Metal Wire

- -W1 Type Carbide Drawing Die for Metal Wires

- -V Type Carbide Drawing Die for Metal Wire

- -LV Type Carbide Drawing Die for Metal Wire

- -E Type Carbide Drawing Die for Metal Wires

- -A Type Carbide Drawing Die for Metal Wires

- -R4 Carbide Drawing Die for Metal Wires

- -R5 Carbide Drawing Die for Metal Wires

- -R6 Carbide Drawing Die for Metal Wires

- -S01 Carbide Drawing Die for Non-Ferrous Metal Wire

- -S10 Carbide Drawing Die for Non-Ferrous Metal Wire

- -S12 Carbide Drawing for Non-Ferrous Metal Wire

- -LSV Wire Die for Steel Cord

- -GS1 Wire Drawing Die

- Tungsten Carbide Bar Drawing Dies

- Tungsten Carbide Tube Drawing Dies

- Tungsten Carbide Tube Drawing Dies Plug

- Carbide Rolls

- Carbide Roll Rings

- Grooved Roller

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Wire Guide Die

- Powder Coating Die

- Peeling Dies

- Custom Drawing Dies

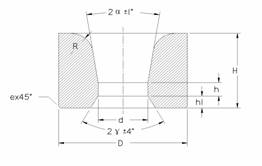

W Type Carbide Drawing Dies for Metal Wire

W type cemented carbide wire drawing dies for ferrous metal are tools widely used in metalworking process. They can stretch large-diameter ferrous metal wires into small-diameter ones. Besides, cross sections of wires can be in various shapes, such as round, octagon, square, hexagon, etc. Drawn wires are commonly used as electrical wires, cables, strings in musical instruments, spokes for wheels, etc. Our cemented carbide dies have passed ISO9001:2000 and are exported to many countries, including America, Germany, Spain, India, Korea, Japan, Malaysia, and so on.

Manufacturing ProcessW type cemented carbide wire drawing dies for ferrous metal are manufactured as following procedures:

1. Selecting Material

2. Rough Machining with Lathes

3. Heat Treatment

4. Pressing Tungsten Steel

5. Linear Cutting

6. Punching Hole

7. Finish Turning

8. Polishing

1. W type cemented carbide wire drawing dies for ferrous metal feature high accuracy. Accuracy of inside diameter can be controlled within 0.005 mm, and concentricity can be controlled within 0.01 mm.

2. W type cemented carbide dies can reduce cross section of wires into diameter ranging from 0.3 mm to 25 mm.

3. Custom drawing dies can be manufactured according to design drawings provided by customers.

4. They feature good wear resistance, high density, long working life and high cost performance ratio.

1. Inform us of what metal material will be drawn before purchase, or tell us the specific types you want. Then, we can help you choose right cemented carbide wire drawing dies for ferrous metal.

2. Custom drawing dies need 15 days to manufacture if you provide physical prototypes. If there is no physical prototype (only with a design drawing), 25 days are needed.

3. Cemented carbide dies are placed in fiber board cases if delivered by ship, and in cartons if by airplane.

4. Payment is through T/T or L/C.

With a specialist team, advanced production facilities and more than 3000 m2 area, TallKee Cemented Carbide is capable of manufacturing various cemented carbide dies no matter these dies are complex in structures or irregular in shapes. Apart from cemented carbide wire drawing dies for ferrous metal, we also produce carbide drawing dies for rods, carbide drawing dies for tubes, custom carbide drawing dies, high speed cemented carbide roll rings, etc...

- Peeling Dies

- Tungsten carbide peeling dies have different specifications, such as round, square, hexagonal, deltoid and other custom shapes. They are broadly ...

- Custom Drawing Dies

- TallKee Cemented Carbide Co., Ltd. is a professional manufacturer and supplier of tungsten carbide drawing dies. Our custom drawing dies ...