- ● Product List

- Tungsten Carbide Drawing Dies

- Tungsten Carbide Wire Drawing Dies

- Tungsten Carbide Bar Drawing Dies

- -S13 Drawing Die for Metal Rods

- -LE Carbide Drawing Die for Metal Rods

- -Carbide Drawing Dies for Square Metal Bars

- -S41 Carbide Drawing Nibs for Rectangle Rods

- -S42 Carbide Drawing Die Nibs for Metal Strips

- -S60 Carbide Drawing Die Nibs for Hexagon Bars

- Tungsten Carbide Tube Drawing Dies

- Tungsten Carbide Tube Drawing Dies Plug

- Carbide Rolls

- Carbide Roll Rings

- Grooved Roller

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Wire Guide Die

- Powder Coating Die

- Peeling Dies

- Custom Drawing Dies

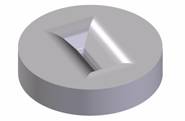

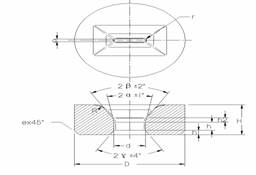

S42 Carbide Drawing Die Nibs for Metal Strips

Cemented carbide drawing dies for metal strips are commonly used in metalworking process. They can size metal rods by shrinking large-diameter metal strips into smaller ones. Carbide drawing die nibs for strips are often performed at room temperature, but sometimes they have to work at elevated temperature when drawing large strips. Shanghai TallKee utilizes rare microcrystal carbides as materials of drawing dies. Besides, high-purity cobalt powder and other special metal powders are applied as binders. We bring in advanced low-pressure sintering technology so that we can manufacture superior cemented carbide drawing dies for metal strips.

Features1. Our drawing die products are featured by wide applications, long working life and high cost performance ratio.

2. We can manufacture custom carbide drawing die nibs for strips according to specifications offered by customers.

3. Cemented carbide drawing dies for metal strips possess superior wear resistance. So, they can work continuously for a long time. Besides, drawing process is accurate.

4. With excellent polishing, carbide drawing die nibs can draw metal rods into strips whose surface is in high quality.

5. In drawing process, adhesion between drawing dies and metal strips is small. Then, drawing dies are more durable, and drawn strip surface is glossier.

6. For carbide drawing die nibs for strips, small friction coefficient can greatly save electric energy and increase working efficiency.

7. Because of high thermal conductivity, heat can be fast released during heat drawing.

8. In cemented carbide drawing dies for metal strips, good corrosion resistance presents advantageous performance when conducting wet drawing, especially when using acidic lubricants.

1. Before choosing suitable products, please tell us what metal materials are to stretch, or tell us your desirable drawing die product.

2. As to custom products, if you provide physical prototypes for reference, 15 days are needed to manufacture specific carbide drawing die nibs for strips. But if no physical prototypes are provided, 25 days are needed.

3. Cemented carbide drawing dies for metal strips are placed in fiber board cases if they are transported by ship, or placed in cartons if they are transported by air.

4. Payment is through T/T or L/C.

During production, Shanghai TallKee applies computer-control reduction furnace, automatic carbide furnace, TPA powder compacting press, low-pressure sintering, etc. Besides, advanced and strict management requires that all products are inspected under standard tests. Our products, including cemented carbide drawing dies for metal strips, have passed ISO9001:2000. They are widely sold at home and abroad. In Indian market, they widely gain good reputations.

- Tungsten Carbide Wire Drawing Dies

- Tungsten carbide wire drawing dies have a certain shaped hole in the center, including round, square, octagonal or other ...

- Tungsten Carbide Tube Drawing Dies Plug

- As a professional tungsten carbide drawing dies manufacturer and supplier, we offer a ...