- ● Product List

- Tungsten Carbide Drawing Dies

- Tungsten Carbide Wire Drawing Dies

- Tungsten Carbide Bar Drawing Dies

- -S13 Drawing Die for Metal Rods

- -LE Carbide Drawing Die for Metal Rods

- -Carbide Drawing Dies for Square Metal Bars

- -S41 Carbide Drawing Nibs for Rectangle Rods

- -S42 Carbide Drawing Die Nibs for Metal Strips

- -S60 Carbide Drawing Die Nibs for Hexagon Bars

- Tungsten Carbide Tube Drawing Dies

- Tungsten Carbide Tube Drawing Dies Plug

- Carbide Rolls

- Carbide Roll Rings

- Grooved Roller

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Wire Guide Die

- Powder Coating Die

- Peeling Dies

- Custom Drawing Dies

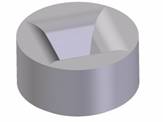

Carbide Drawing Dies for Square Metal Bars

Tungsten carbide drawing dies for square metal rods are commonly used to shrink cross sections of square metal bars into smaller ones. They are applied in steel industry, automobile industry, electrical industry, etc. Available metal materials are both ferrous metal and non-ferrous metal. Our TC square rod drawing dies are manufactured with microcrystal carbides and auxiliary binders like high-purity cobalt powder. During processing, top low-pressure sintering technology is performed to maintain superior performance of tungsten and increase other performance by 1/4. Besides, cobalt powder endows drawing dies with strong toughness.

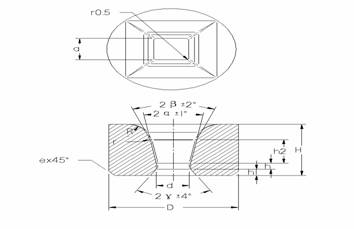

StructuresTungsten carbide drawing dies for square metal rods have six important structures which respectively are entrance area, lubrication area, working area, sizing area, exit area and exit cone angle.

1. Entrance area plays a transition role in facilitating drawing materials into working area so that metal materials would not be scratched by the edge of die hole.

2. Lubrication area is to store lubricant so that drawing process is completed successfully.

3. Working area of TC square rod drawing dies is where metal materials begin to be stretched into new rods. Principles to select working area length are as follows:

(1) Working area used for stretching soft metals is shorter than that for hard metals.

(2) Working area used for small-diameter rods is shorter than that for large-diameter rods.

(3) Working area used under wet lubrication is shorter than that under dry lubrication.

4. In tungsten carbide drawing dies for square metal rods, sizing area decides the final dimension of metal materials. Length of sizing area varies with different hardness. If sizing area is too long, friction will increase, which has negative impact on working life of drawing dies. But if sizing area is too short, change of cone angle will influence the size of metal materials.

5. Exit area is the last part passed by metal materials. It is designed to protect sizing area from cracking. Exit cone angle is to protect completed metal rods.

1. Maximum diameter of TC square rod drawing dies is 120 mm. Diameter of sizing area ranges from 1.8 mm to 55 mm.

2. A wide range of types are provided to meet different applications. Besides, Shanghai TallKee can manufacture custom tungsten carbide drawing dies for square metal rods according to specifications offered by clients.

3. They are featured by high wear resistance, excellent polishing, small adhesion, small friction coefficient, high thermal conductivity and good corrosion resistance.

1. To choose suitable products, please tell us what metal materials are to stretch or which types of TC square rod drawing dies are desirable in advance.

2. As to custom products, if you provide physical prototypes for reference, custom tungsten carbide drawing dies for square metal rods can be manufactured in 15 days. But if no prototypes are offered, 25 days are needed.

3. Cargos are packaged with fiber board if they are delivered by ship, and with cartons if delivered by air.

4. Payment is through T/T or L/C.

Shanghai TallKee owns a specialist team and various advanced production facilities. It is capable of manufacturing many kinds of cemented carbide dies no matter these dies are complex in structures or irregular in shapes. Our products, including tungsten carbide drawing dies for square metal rods, are widely sold at home and abroad. Last year, our sales volume in domestic market was 15 million RMB, and in overseas market was 20 million RMB.

- Custom Drawing Dies

- TallKee Cemented Carbide Co., Ltd. is a professional manufacturer and supplier of tungsten carbide drawing dies. Our custom drawing dies ...

- Peeling Dies

- Tungsten carbide peeling dies have different specifications, such as round, square, hexagonal, deltoid and other custom shapes ...