- ● Product List

- Tungsten Carbide Drawing Dies

- Tungsten Carbide Wire Drawing Dies

- Tungsten Carbide Bar Drawing Dies

- Tungsten Carbide Tube Drawing Dies

- Tungsten Carbide Tube Drawing Dies Plug

- -S30 Carbide Drawing Die for Plugs

- -S30-A Carbide Drawing Die for Plugs

- -S30-AB Carbide Drawing Die for Plugs

- -S31 Carbide Drawing Die for Plugs

- Carbide Rolls

- Carbide Roll Rings

- Grooved Roller

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Wire Guide Die

- Powder Coating Die

- Peeling Dies

- Custom Drawing Dies

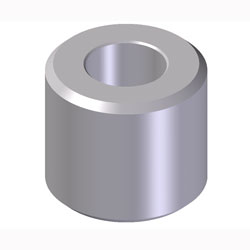

S31 Carbide Drawing Die for Plugs

S31 tungsten carbide dies for mandrels are important tools in metalworking. They can reduce cross sections of metal mandrels by drawing these mandrels through drawing holes. Cemented carbide drawing dies for plugs are often working at temperature, which is known as cold drawing. But if mandrels are in large size, drawing may be performed at higher temperature. Shanghai TallKee utilizes rare microcrystal carbides and high-purity cobalt powder binder for production of drawing dies. Besides, advanced low pressure sintering technology is applied to retain advantageous features of tungsten. At the same time, other beneficial performances are increased by 1/4.

Compositions1. During production of S31 tungsten carbide dies for mandrels, we apply first-hand raw materials. Then production cost is greatly reduced.

2. We can manufacture custom drawing dies according to specific parameters or design drawings provided by clients.

3. With superior wear resistance, drawing dies are durable. Besides, mandrel drawing is accurately performed.

4. Small adhesion and excellent polishing assure that cemented carbide drawing dies for plugs can stretch products which are with glossy quality surface.

5. Surface friction is small, which can economize electric energy and greatly increase working efficiency.

6.S31 tungsten carbide dies for mandrels can keep superior working performance when performing heat drawing and wet drawing, because they possess high heat thermal conductivity and great corrosion resistance.

1. To help you choose suitable products, please tell us what types of drawing dies you want and what metal materials are to stretch.

2. 15 days are needed to manufacture custom cemented carbide drawing dies for plugs if physical prototypes are offered. Other, 25 days are needed.

3. Cargos are packaged with fiber board cases if they are delivered by ship. But if they are delivered by air, they are placed in cartons.

4. Payment of S31 tungsten carbide dies for mandrels is though T/T or L/C.

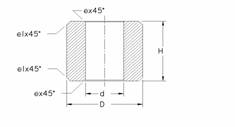

| New Type | Old Type | Dimension (mm) | Reference Dimension (mm) | |||

| D | H | d | e1 | e | ||

| S31-0142500-7.0 | S31-14 | 14 | 25 | 7.0 | 1.0 | 0.5 |

| S31-0152500-7.0 | S31-15 | 15 | 25 | 7.0 | 1.0 | 0.5 |

| S31-0162500-7.0 | S31-16 | 16 | 25 | 7.0 | 1.0 | 0.5 |

| S31-0172500-8.0 | S31-17 | 17 | 25 | 8.0 | 1.0 | 0.5 |

| S31-0182500-8.0 | S31-18 | 18 | 25 | 8.0 | 1.0 | 0.5 |

| S31-0193000-10.0 | S31-19 | 19 | 30 | 10.0 | 1.0 | 0.5 |

| S31-0203000-10.0 | S31-20 | 20 | 30 | 10.0 | 1.0 | 0.5 |

| S31-0213000-10.0 | S31-21 | 21 | 30 | 10.0 | 1.0 | 0.5 |

| S31-0223000-10.0 | S31-22 | 22 | 30 | 10.0 | 1.0 | 0.5 |

| S31-0233000-12.0 | S31-23 | 23 | 30 | 12.0 | 1.0 | 0.5 |

| S31-0243000-12.0 | S31-24 | 24 | 30 | 12.0 | 1.0 | 0.5 |

| S31-0253000-12.0 | S31-25 | 25 | 30 | 12.0 | 1.0 | 0.5 |

| S31-0263000-12.0 | S31-26 | 26 | 30 | 12.0 | 1.0 | 0.5 |

| S31-0273000-12.0 | S31-27 | 27 | 30 | 12.0 | 1.0 | 0.5 |

| S31-0283500-16.0 | S31-28 | 28 | 35 | 16.0 | 1.0 | 0.5 |

| S31-0293500-16.0 | S31-29 | 29 | 35 | 16.0 | 1.0 | 0.5 |

| S31-0303500-16.0 | S31-30 | 30 | 35 | 16.0 | 1.0 | 0.5 |

| S31-0313500-16.0 | S31-31 | 31 | 35 | 16.0 | 2.0 | 0.5 |

| S31-0323500-16.0 | S31-32 | 32 | 35 | 16.0 | 2.0 | 0.5 |

| S31-0333500-20.0 | S31-33 | 33 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0343500-20.0 | S31-34 | 34 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0353500-20.0 | S31-35 | 35 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0363500-20.0 | S31-36 | 36 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0373500-20.0 | S31-37 | 37 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0383500-20.0 | S31-38 | 38 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0393500-20.0 | S31-39 | 39 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0403500-20.0 | S31-40 | 40 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0413500-20.0 | S31-41 | 41 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0423500-20.0 | S31-42 | 42 | 35 | 20.0 | 2.0 | 0.5 |

| S31-0434000-22.0 | S31-43 | 43 | 40 | 22.0 | 2.0 | 0.5 |

| S31-0444000-22.0 | S31-44 | 44 | 40 | 22.0 | 2.0 | 0.5 |

| S31-0454500-26.4 | S31-45 | 45 | 45 | 26.4 | 2.0 | 0.5 |

| S31-0464500-26.4 | S31-46 | 46 | 45 | 26.4 | 2.0 | 0.5 |

| S31-0474500-26.4 | S31-47 | 47 | 45 | 26.4 | 2.0 | 0.5 |

| S31-0484500-26.4 | S31-48 | 48 | 45 | 26.4 | 2.0 | 0.5 |

| S31-0504500-26.4 | S31-50 | 50 | 45 | 26.4 | 2.0 | 0.5 |

We can manufacture 3 million tungsten carbide dies and 500 T cemented carbide workblanks every year. Last year, our sales volume in domestic market was 15 million RMB, and in overseas market was 20 million RMB. Our products, including S31 tungsten carbide dies for mandrels, are widely sold at home and abroad. They are mainly exported to North American countries, Japan, Korea, India, Taiwan, Southeast Asia, etc.

- Tungsten Carbide Tube Drawing Dies

- Tungsten carbide tube drawing dies are designed with round, square, hexagon and other special shapes. They are used for drawing various ...

- Tungsten Carbide Bar Drawing Dies

- Bar drawing dies in manufacturing industry are usually made of carbides or tool steel. Rod or bar drawing is a term used to express one of ...